Discuss the types, characteristics, and applications of boards in different scenarios.

I. Types and characteristics of boards

Boards refer to materials cut and pressed into specified dimensions and thickness from wood or other raw materials, widely used in construction and furniture manufacturing. Common types of boards include solid wood boards, plywood, medium-density fiberboard, particleboard, and laminated veneer lumber. Different types of boards have their unique characteristics:

- Solid wood boards: Solid wood boards have natural texture and color, offering good decorative and textural qualities, suitable for high-end furniture and decorations.

- Plywood: Plywood is made by bonding multiple layers of wood together, providing high strength and good stability, suitable for large furniture and building structures.

- Medium-density fiberboard (MDF): MDF is made from wood chips and glue compressed together, with a smooth surface and easy machinability, applicable for furniture manufacturing and decoration.

- Particleboard: Particleboard is made by compressing wood chips and glue, offering certain strength and compressive resistance, suitable for furniture manufacturing, packaging boxes, etc.

- Laminated veneer lumber (LVL): LVL is made by stacking multiple layers of wood veneers together, offering high strength and resistance to deformation, suitable for building structures and furniture manufacturing.

II. Applications of boards in different scenarios

- Furniture manufacturing: In the furniture manufacturing industry, choosing the right boards is crucial as it determines the quality and appearance of the furniture. Solid wood boards are suitable for making high-end furniture, enhancing the quality and class of the furniture; plywood and MDF are suitable for making large-scale furniture, ensuring stability and strength.

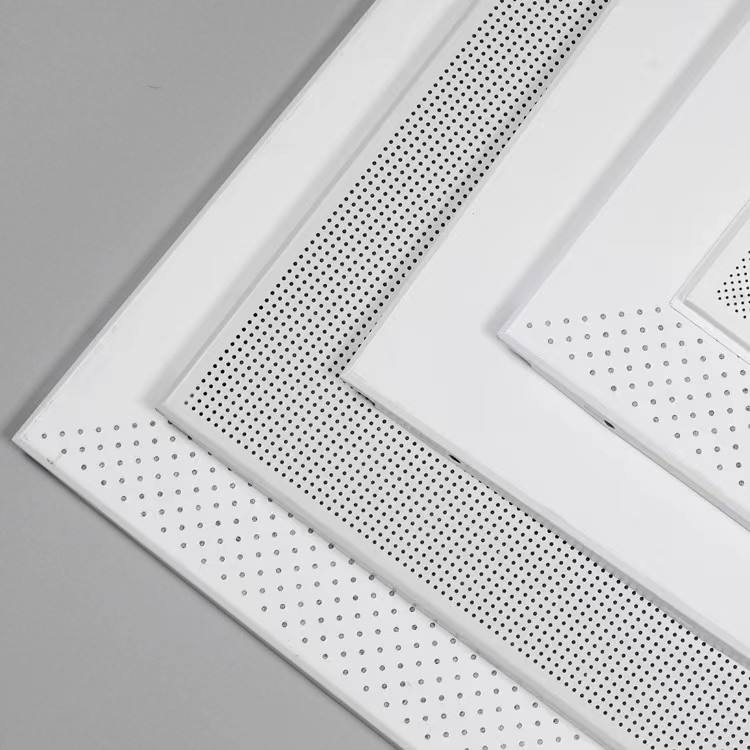

- Architectural decoration: Boards play an important role in architectural decoration, such as flooring, wall panels, ceilings, etc. Different types of boards can bring different styles and atmospheres to interior decoration, enhancing the aesthetics and practicality of the space.

- Industrial manufacturing: In the industrial manufacturing sector, different types of boards meet various needs. Lightweight, high-strength carbon fiber boards are suitable for the aerospace industry; heat-resistant, wear-resistant fiberglass boards are suitable for automotive manufacturing. Different types of boards cater to the performance requirements in industrial manufacturing.

III. The importance of choosing the right boards

Choosing the right boards is crucial for various applications. Suitable boards can improve product quality, extend lifespan, and reduce maintenance costs, providing assurance for project success. Therefore, when selecting boards, project requirements should be fully considered, taking into account factors like material performance, appearance, price, etc., to achieve the best results.

In conclusion, boards as an important material for construction and furniture manufacturing play an irreplaceable role in various scenarios. Choosing the right boards can have a crucial impact on project success and should be given careful consideration in practical applications.